Cable run is a fundamental concept in the world of networking, acting as the physical conduit that bridges the gap between various network components across different locations within a premise.

This article delves into the intricacies of cable run, exploring its significance in the installation of premise cabling, the different types of cable runs employed to connect network elements, and the standards guiding the selection of cable grades. By understanding cable runs, IT professionals and network engineers can ensure their network infrastructure is not only robust and efficient but also compliant with safety and building codes.

Index

- What is Cable Run?

- Types of Cable Runs and Their Applications

- Horizontal Cable

- Vertical Cable

- Understanding Cable Grades and Compliance

- The EIA/TIA Wiring Standards Explained

- Best Practices for Installing Cable Runs

- Common Challenges in Cable Run Installation and Solutions

- The Future of Cable Runs in Networking

- References

1. What is Cable Run?

A cable run represents the length of cable that connects two distinct network components within a facility, enabling communication and data transfer between devices that are not immediately adjacent. The process of laying cable runs constitutes the core of installing premise cabling systems, ensuring that every corner of a customer’s premises is network-ready.

Laying cable runs is the main work of installing premise cabling in a customer premises.

2. Types of Cable Runs and Their Applications

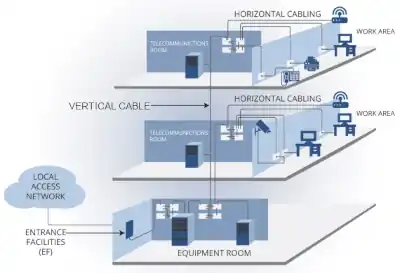

Cable runs are categorized based on their orientation and function within a building’s network infrastructure:

- Horizontal Cable: This type of cable run is primarily used within a single floor, extending through spaces above ceilings or below floors to connect workstations, devices, or wall plates to the central wiring closet. It facilitates the distribution of data and communication services to individual users or devices. Horizontal cabling often runs through spaces that double as air return paths for HVAC systems. In such cases, plenum-rated cables are mandatory to comply with building codes and safety standards. These cables ensure that, in the event of a fire, smoke and toxic fume emissions are minimized.

- Vertical Cable: Also known as backbone cabling or Riser Cable, vertical cable runs span across multiple floors, connecting the wiring closets of different levels to the main distribution frame or equipment room. This setup is crucial for maintaining the integrity and performance of the building’s overall network system. Riser cables are designed to prevent the vertical spread of fire between floors.

Different grades of cabling must be used for different runs to ensure compliance with building codes and safety standards. Examples include PVC (polyvinyl chloride) cabling and plenum cabling. The EIA/TIA wiring standards specify guidelines for using cable types and grades.

3. Understanding Cable Grades and Compliance

The choice of cable for different runs is influenced by various factors, including the cable’s fire resistance, smoke production, and the environmental conditions it will be exposed to. Common cable grades include:

- PVC (Polyvinyl Chloride) Cabling: Widely used for its flexibility and durability, PVC cabling, however, is not suitable for plenum spaces due to its smoke production when burned.

- Plenum Cabling: Specially designed to meet the stringent fire safety standards of plenum spaces, plenum cabling emits low smoke and no toxic fumes, making it a safer choice for areas with air circulation for heating and air conditioning systems.

4. The EIA/TIA Wiring Standards Explained

The Electronics Industry Alliance/Telecommunications Industry Association (EIA/TIA) wiring standards serve as a cornerstone for network cabling practices, setting the stage for high-quality, reliable network infrastructure. These standards, notably the TIA/EIA-568 family, are designed to harmonize the design and installation of cabling systems across various environments, ensuring they meet the demands of modern communication technologies.

Key Aspects of EIA/TIA Standards:

- Structured Cabling: These standards outline the architecture for telecommunication cabling systems in commercial buildings, including guidelines for data centers, offices, and apartment buildings. They define how to organize and manage cabling to support multiple hardware uses and facilitate future upgrades or reconfigurations.

- Cabling Components: Specifications include details on the types of cables (e.g., Category 5e, 6, 6a, 7), connectors, patch panels, and other components that should be used. This ensures compatibility and performance across different manufacturers.

- Performance Benchmarks: The standards set performance benchmarks for transmission speed, signal integrity, and crosstalk limits. These benchmarks ensure that the installed cabling system can support the intended data rates and bandwidth requirements of the network.

- Installation Practices: Guidelines cover best practices for the installation process, including cable laying, termination, and testing procedures. This ensures that the physical installation does not compromise the cabling system’s performance.

Adherence to EIA/TIA standards is crucial for ensuring that network installations are capable of delivering the intended communication services, both now and in the future, while maintaining the flexibility to adapt to technological advancements.

5. Best Practices for Installing Cable Runs

Beyond the foundational steps of conducting site surveys, labeling, and documentation, several additional best practices are vital for the successful installation of cable runs:

- Cable Management: Employ cable management solutions such as trays, racks, and conduits to organize cables and protect them from physical damage. Proper cable management aids in maintaining an orderly system, simplifies maintenance, and enhances airflow, reducing the risk of overheating.

- Testing and Certification: After installation, each cable run should be tested for performance according to EIA/TIA standards. Use certified testing equipment to verify that the installation meets or exceeds the required performance criteria, ensuring the network’s reliability and functionality.

- Future-Proofing: Consider the future growth and technological evolution of the network during the planning stage. Install conduits and additional capacity to accommodate more cables or higher-grade cables to ease future upgrades without significant disruptions.

6. Common Challenges in Cable Run Installation and Solutions

- Environmental Factors: Environmental conditions such as moisture, temperature extremes, and electromagnetic interference (EMI) can affect cable performance. Use appropriate cable types (e.g., outdoor-rated, shielded) and installation techniques to mitigate these effects.

- Physical Space Limitations: In densely populated or older buildings, finding routes for new cable runs can be challenging. Creative solutions like using existing pathways, optimizing rack layouts, or employing smaller diameter cables can help overcome space constraints.

- Regulatory Compliance: Navigating the complex landscape of local building codes and regulations can be daunting. Engage with local authorities early in the planning process to understand specific requirements and avoid costly revisions or penalties.

7. The Future of Cable Runs in Networking

The future landscape of cable runs in networking is poised for significant evolution, driven by developments such as:

- Fiber Optic Advances: The increasing adoption of fiber optic cables for their high-speed and bandwidth capabilities will continue to shape the future of network cabling. Innovations in fiber technology, such as bend-insensitive fibers, are making installations more flexible and resilient.

- Wireless Integration: The rise of wireless technologies and the Internet of Things (IoT) will influence the design and implementation of cable runs. Hybrid networks that integrate wired and wireless infrastructure will become more common, requiring thoughtful planning to ensure seamless connectivity.

- Sustainability: Environmental considerations will play a larger role in cabling decisions. Eco-friendly materials, recycling programs for old cables, and energy-efficient design principles will become increasingly important in reducing the environmental impact of network infrastructures.

8. References

- EIA/TIA Wiring Standards Documentation

- “Network Cabling Illuminated” (2006) by Robert Shimonski, Richard T. Steiner, Sean M. Sheedy